Materials

Cement particle boards (TsSP) 12mm

Cement particle boards are monolithic slabs with a density of 1250-1400 kg / m3, 12 mm thick with a smooth or hard surface.

ECOLOGICAL

DSP is an environmentally friendly material. DSP does not contain phenolic, formaldehyde and other toxic compounds. The main chemical binder is cement.

The plates are made by pressing a molded mixture consisting of softwood chips, portland cement, minerals and water.

High quality DSP is ensured by strict quality control in accordance with the European standard EN 634-2.

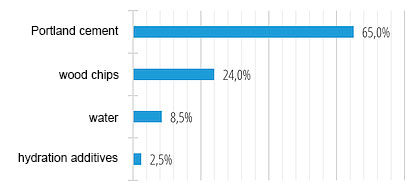

The composition of the DSP as a percentage of the total mass is:

The slab is a solid solid material. The release of dust, gases and vapors from the stoves is impossible due to the mineralization of the contained substances and the applied production technology.

FIRE SAFETY

In case of fires in the rooms, the plates do not form smoke and do not emit toxic gases and vapors.

RELIABILITY

DSP is primarily a structural material that gives frame structures rigidity. In the production process, the particle-cement carpet is formed of four layers: the outer layers are made of small, the inner ones of larger fractions of chips. Dialed carpet is pressed.

It should be noted another property – the possibility of using structures of buildings with cladding of DSP in earthquake-prone areas and buildings of high-rise.

RESISTANCE TO MOISTURE

Most commonly, slabs are used as cladding panels with a wooden frame in low-rise housing construction. Plates not only give the wooden frame additional rigidity, but also serve as protection against weathering. Bearing and enclosing structures of a house with DSP lining because of its smooth surface do not require additional treatment. DSP has a significant advantage in water absorption compared to other plate materials.

BIOS STABILITY

DSP resists the effects of fungi, tree beetles, domestic rodents. It is important to note that this biostability is not achieved due to the introduction of any special antiseptics into the DSP, and not due to the surface treatment with an antiseptic. Antiseptic is formed in the mass of the DSP itself in the process of turning cement into concrete, as a by-product of this process is calcium hydroxide, which creates a strongly alkaline environment that prevents the development of mold fungi.

Gypsum chipboard moisture resistant (GSPV) 12mm

Gypsum chipboard (GSPV) is a modern, high-quality and high-tech material designed for interior decoration.

GSP panels distinguish among its competitors undeniable advantages – strength and practicality, high performance fire safety and fire resistance, environmental friendliness, biostability and many other factors. They allow you to call gypsum chip board best on this one moment analog drywall. Technology production of SHG excludes adhesives and resins in composition, this determines the high class environmental and health safety person.

The gypsum chipboard achieves all these characteristics by combining the best properties of gypsum and wood in it. The molding mass consisting of gypsum, uniformly reinforced with wood chips throughout the volume, and water is pressed by the semi-dry method. The outer surface is obtained in this light, smooth and compacted.

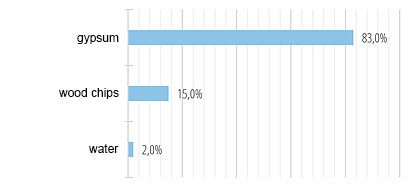

In percentage terms, the composition of the SHG looks like this:

In addition, the SHG also has a low degree of noise and heat conduction, the surface of the material is perfectly smooth and even. The combination of these qualities makes the slabs SGPV the best option for interior decoration of the room and floor elements. You can use them for walls, floor, ceiling, as well as for installation of interior partitions. GSPV is also used for leveling walls, installing window slopes and window sills, installing ceilings and dry floor screed. GSPV, which has a high level of moisture resistance, can be used in rooms with a high level of humidity – kitchens and bathrooms.

ADVANTAGES OF GSPV

- High strength characteristics.

- Ecological safety, which allows to safely use the material for interior decoration in schools, kindergartens, hospitals, clinics;

- Fireproof. Gypsum chip plates do not burn and do not emit harmful substances when heated;

- Simplicity and speed of installation. To work with this material does not require special knowledge and skills, just a little experience in finishing work.

- Moisture resistance. SHSPV is not deformed and does not collapse even with a high level of humidity in the room;

- Biostability Plates are not subject to rotting, the effects of fungus, the occurrence of mold.

TECHNICAL SPECIFICATIONS SHG:

- Density no more, (kg / m3): 1250

- Release moisture,% (by weight of dry matter), no more than: 2 ± 0.5

- Flexural strength MPa, not less, for thicknesses of 8-10: 8.0

- Flexural strength MPa, not less, for thicknesses of 12-16: 7.0

- Thickness swelling in 2 hours,% not more than: 0.2

- Water absorption for 2 hours,% not more: 10

- Linear expansion with a change in humidity (RH30% -KP85%), no more than: 0.07

Thermal insulation PAROC UNS 37z

PAROC UNS 37z is heat insulating and sound absorbing material made in the form of plates. For its production is used rock wool from rocks basalt group and low phenol binder. With this content organic components in the composition PAROC UNS 37z ranges from 2 to 4% by weight..

MAIN PROPERTIES AND OPERATIONAL CHARACTERISTICS

- A characteristic feature of PAROC UNS 37z slabs is the open porosity of the material, which ensures its high thermal insulation properties and vapor permeability. At the same time, the density of the plates is high enough to become a reliable obstacle to convective heat exchange and an excellent protection against heat loss in any climatic conditions;

- Among the performance characteristics of PAROC UNS 37z, it should be noted that it is resilient and the ability to keep the shape of the slab constant throughout the life of the stack, both on a horizontal and vertically positioned surface. In addition, PAROC UNS 37z plates do not shrink, bend well and are easy to process;

- PAROC UNS 37z plates are considered to be non-combustible heat-insulating material, which can be used in the temperature range from -65 to +200 C. It is allowed to use the plates at temperatures up to +750 C, but binder components evaporate and the plates lose their elasticity, while maintaining insulation and sound absorbing properties;

- PAROC UNS 37z slabs are not susceptible to corrosion and are also resistant to fungal microflora and mildew. The term of their operation is not less than 70 years. If necessary, the plates can be reused.

DECKER 135 super diffusion membrane

DECKER three-layer roofing membranes are an original product produced using the ultramodern molecular bonding technology of the ULTRASONIC layers. Only the technology “ULTRASONIC” allows to achieve the highest strength of the membrane while maintaining high diffusion properties. Also, the ULTRASONIC technology does not damage the layers of materials being joined and only for this reason DECKER membranes have the highest service life – from 50 years and more.

Vapor barrier DECKER REFLEXX Active

The vapor barrier four-layer active membrane DECKER REFLEXX Active with a reflective layer of aluminum is an original product, produced using state-of-the-art technology of molecular bonding of layers “ULTRASONIC”. This membrane allows you to actively regulate the vapor transmission ability and to dry the insulation and wooden structures.

Oriented strand board OSB-3 10mm

OSB-3 is a multi-layered (3-4 layers or more) sheet consisting of wood chips (thin chips) glued with various resins. The chips in the layers of the plate have a different orientation – in the outer longitudinal, in the inner transverse. OSB-3 – used in the manufacture of load-bearing structures in conditions of high humidity.

ADVANTAGES:

- High reliability claimed material properties confirmed on practice;

- High strength – physical mechanical performance of OSB-3 2.5 times higher than chipboard;

- Moisture resistance – the material does not collapse and retains its strength characteristics when in water for 1 day (swelling ratio is about 10%);

- Quality manufacturing stability;

- Low weight;

- High rate of deformation at fracture;

- OSB plate is not subject to damage by insects

Construction Lumber chamber drying

In the production of elements of a frame-panel house, only calibrated and dried (up to 14%) lumber with a strength class of C18, C24, C30 is used.

In the MiTek equipment produced on metal-toothed plate farms only MiTek certified software is used, as well as sawn timber sorted by strength classes certified by a specialist.