RAILWAY FARM MiTek

The production company Zenvile provides services for the design and manufacture of trusses and trusses using metal-toothed plates (MW) in MiTek technology.

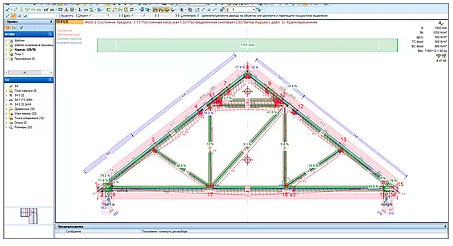

Thanks to the licensed MiTek software, the calculation is made roof of a building of any complexity. The designed structure is guaranteed to provide the specified bearing capacity in accordance with the requirements of building codes for snow, wind and operating loads.

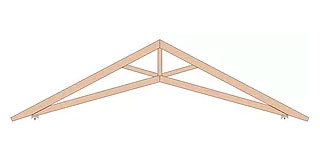

MiTek technology is the design and factory production of wooden trusses connected in knots by metal plates with stamped teeth. The production of such structures originated in North America in the middle of the last century, during the last forty years this idea received its further development in European countries (Switzerland, Belgium, Germany). Such structures are used in buildings for various purposes (residential buildings and attic floors, production facilities, cultural facilities, sports facilities). A wide range of applications due to the ability to span spans up to 30m without internal supports.

The system is based on trusses connected in knots by steel fasteners with stamped teeth, which are called connecting plates.

Certificates:

MiTek connecting plates are made in a wide assortment of galvanized sheet steel various thickness (T150, GNA20, M14). Most often used steel with a thickness of 1-2 mm quality characteristics.

Main advantages:

- All nodes are fastened together by metal toothed plates under the press, which allows the manufacture of truss systems up to 30 m without additional supports;

- Production takes 2 days or more, depending on the volume of the order;

- Fast installation speed at the construction site. Minimizing costs and human resources – a maximum of 4 people are needed to assemble the roof structure.

- The use of sawn timber, passed the process of technical drying (humidity not more than 18%);

- Our designs can withstand:

- wind loads up to 150 kg / m²

- seismic loads up to 11 points

- snow loads up to 350 kg / m²

Roof panels

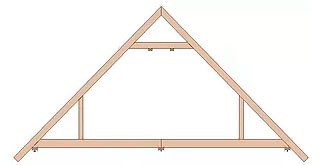

Gable bescherdachnaya

Gable farm scissors

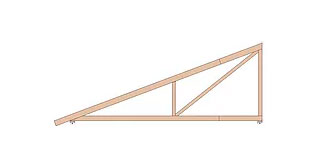

Single pitch cordless

Gable with attic

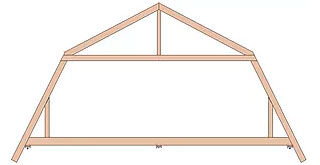

Mansard